Square aluminum shell PACK line

Automotive Electronics

1.

Head Up Displays (HUD)

2.

Wireless Power Charger (WPC)

3.

Precision Kinematic System (PKS)

4

Digital Access Solution (DAS)

Smart Devices

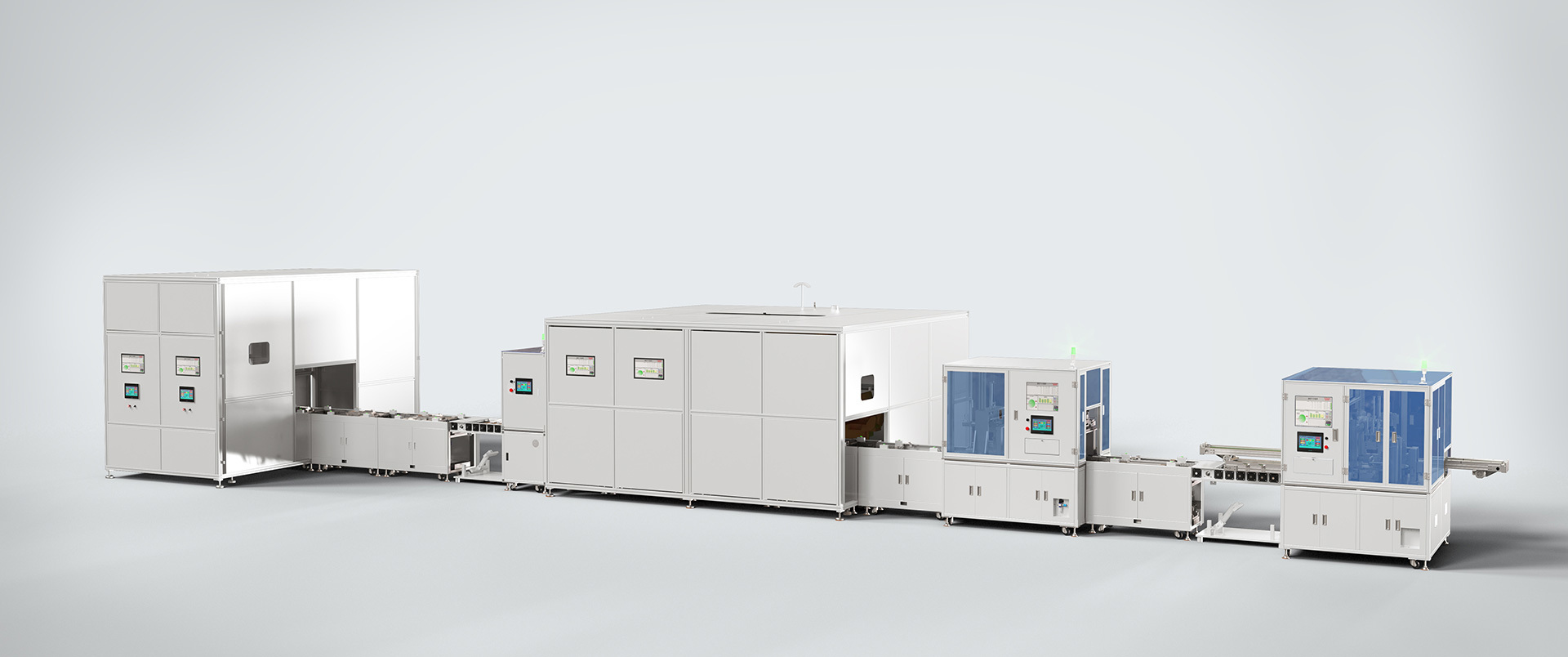

Square aluminum shell PACK line

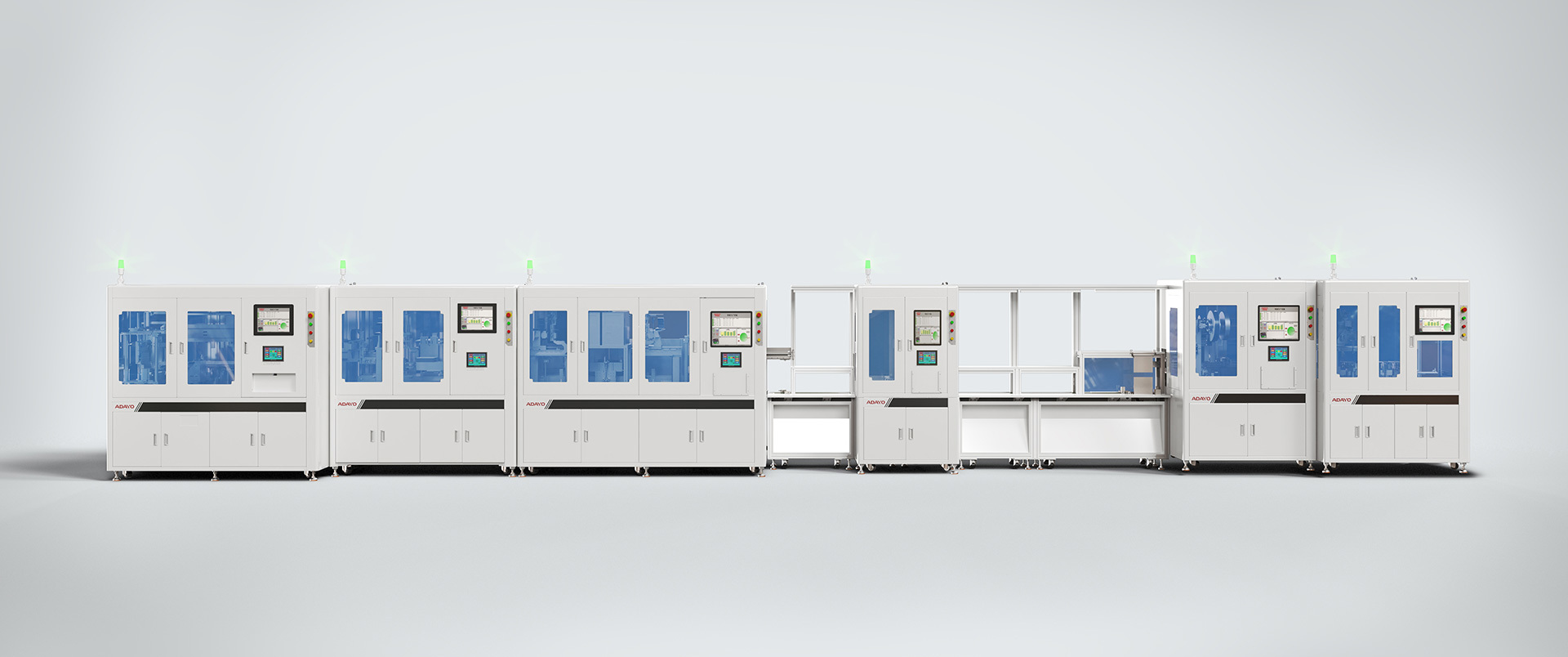

Power PACK line

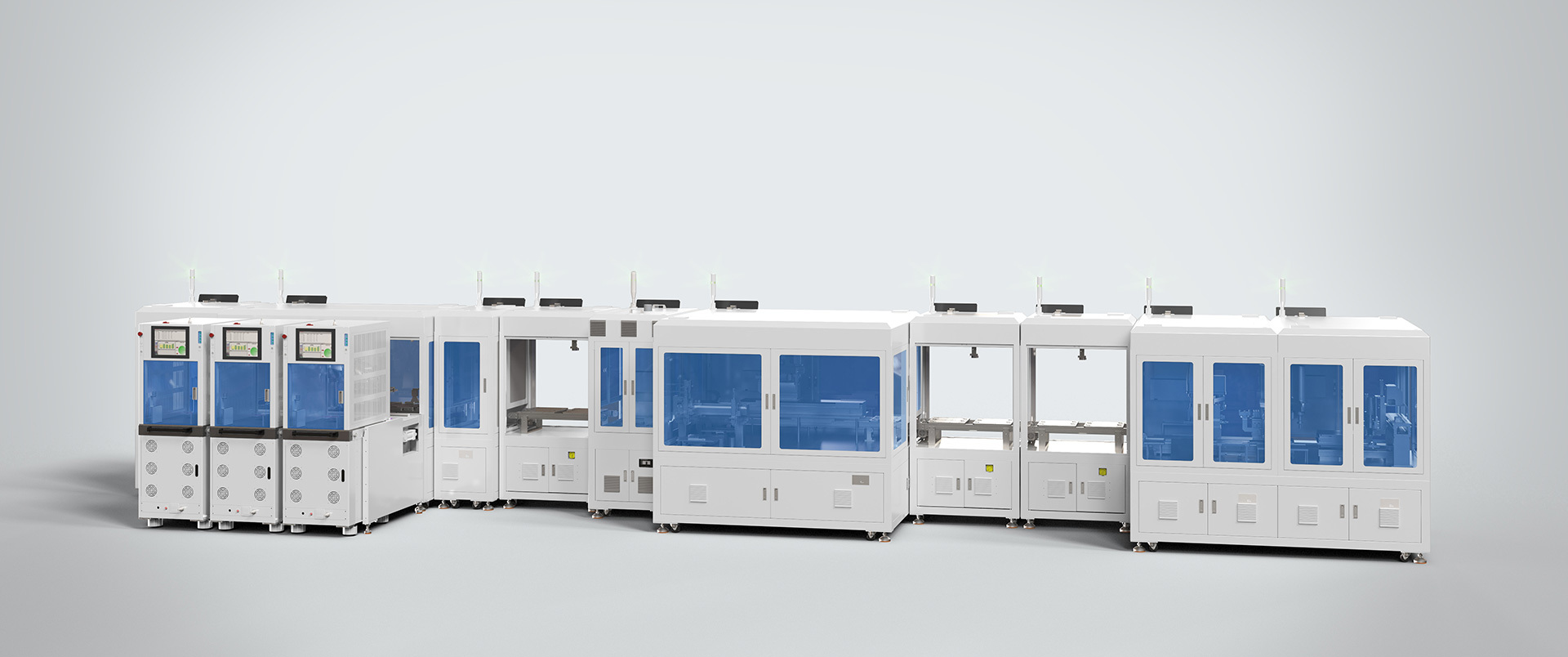

Tool class PACK automatic line

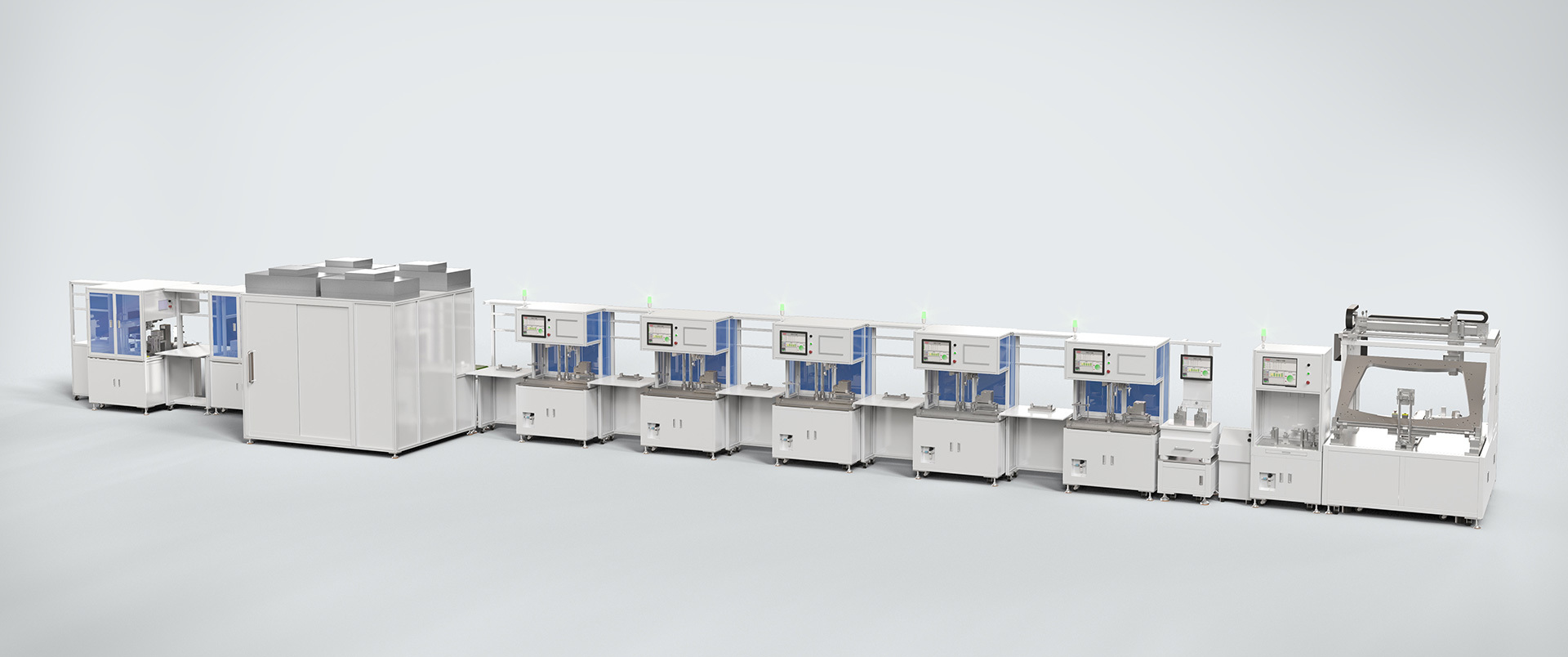

Garden type PACK line

Sweeping robot PACK line

Mobile phone battery protection board automatic line

Automatic line for notebook battery protection board

HUD assembly line

The automatic line of CWC

Square aluminum shell PACK line

Power PACK line

Tool class PACK automatic line

Garden type PACK line

Sweeping robot PACK line

Mobile phone battery protection board automatic line

Automatic line for notebook battery protection board

HUD assembly line

The automatic line of CWC

News

About Us

Since brand been created

China Automotive New Supply Chain

Automotive electronics and Intelligent manufacturing

Huizhou Huayang Multimedia Electronics Co., Ltd. was established in 2001. It is a wholly-owned subsidiary of Huizhou Huayang Group Co., Ltd. with a registered capital of HK $0.296 billion. It is a national high-tech enterprise. The company is committed to the research and development, production and sales of head-up display (HUD), wireless charging, sports institutions, digital keys and intelligent equipment, and has cooperation with many well-known automobile brand enterprises and auto parts enterprises at home and abroad.

Copyright©Huizhou Huayang Multimedia Electronics Co., Ltd. All Rights Reserved